Conveyor Belt Tunnel Parts Washers

Products

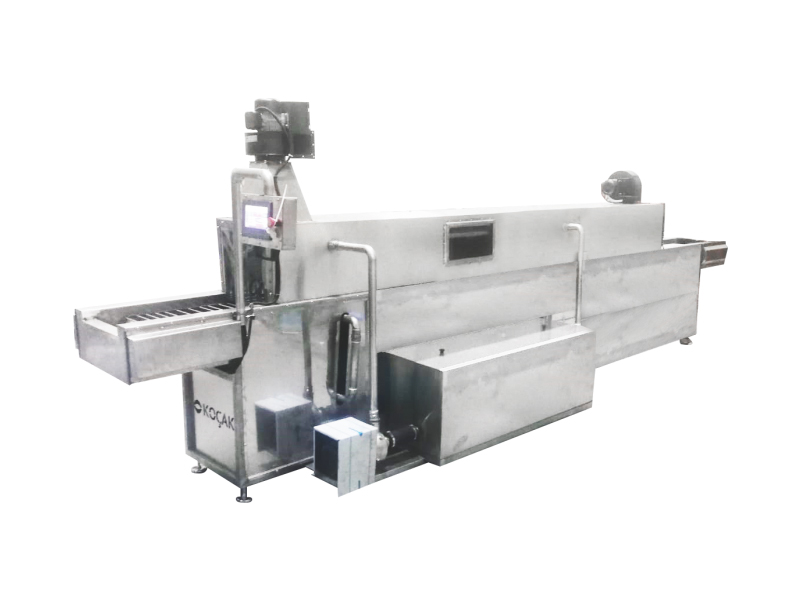

Conveyor Belt Tunnel Parts Washers

Details

The materials placed directly on the conveyor belt or in baskets pass through spray washing, spray rinsing, air blowing, and drying units with adjustable belt speeds, and reach the unloading platform. Continuous washing can be performed with manual or conveyor feeding. The washing process is designed to ensure that every point of the material is scanned with nozzles. Washing pressures, nozzle placements, and processes can be adjusted according to the type of oil, chips, and residues to achieve the desired surface cleanliness. Units can be added or removed according to the process requirements. Our company can manufacture washing machines with the desired dimensions and specifications.

APPLICATION AREAS

- Automotive industry

- Aerospace industry

- Shipbuilding industry

- Defense industry

- Metal industry

- Coating industry

- Food industry

Technical Specifications

| Feature | Value |

|---|---|

| Machine Dimensions | Optional |

| Cabin Dimensions | Optional |

| Washing Line | Pre-wash / Wash / Rinse / Pure water rinse |

| Drying Chamber and Fan | Standard - Optional |

| Pump Power and Quantity | 3 hp - Optional |

| Pump Structure | Stainless steel - Ceramic seal |

| Heater Power | Optional |

| Electric/Phase | 380 V / 3 |

| Electric System | ABB / SCHNEIDER |

| Belt Safety System | Standard |

| Thermal and Motor Protections | Standard |

| Timer | 0-90 min |

| Thermostat | 0-120 °C |

| Body Structure | AISI Stainless Steel |

| Belt and Chain Structure | AISI Stainless Steel |

| Total Tank Volume | Optional |

| Loading System | Manual |

Get a Quote

Get Offer